Definition And Working Of VCSEL

Semiconductor lasers such as FP, DFB, VCSEL and more are essential devices for regulating and improving the Internet and communication sector in the world. Laser’s outstanding properties such as high efficiency of the electrical energy into photons, excellent reliability, small footprint, modulation bandwidth, and low cost have made it a principle component in various communication applications.

Vertical Cavity Surface Emitting Laser is one such laser that is largely used in various industrial and military applications. Let's know what is VCSEL in detail.

What is

VCSEL?

VCSEL is the type of semiconductor laser diode with laser beam emission perpendicular from the top surface, as opposed to conventional edge-emitting semiconductor lasers which emit from surfaces. Compared to conventional edge-emitting light diodes, VCSEL emits light or a vertical beam from its top surface.

Now let us comprehend how Vertical Cavity Surface Emitting Laser works. Note that, as it is challenging to cover the whole working process in detail, we have covered fundamental points only.

|

| An edge-emitting diode vs VCSEL |

Working of VCSEL

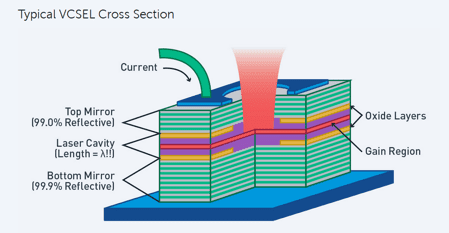

A typical

Vertical-Cavity Surface-Emitting Laser is made of several layers. The top is

layer is electrical contact for current injection. The next layer, i.e. the

second layer, is the high reflectively mirror with having 99% reflectivity. The

next– the third layer is an oxide layer which develops a light-emitting window

so that the light beam can be converted into the circular beam.

The next

layer– the center layer in the VCSEL is the laser cavity. It is the active gain

region where lasing happens. Again there is an oxide layer below the center

layer to confine the light. And the last layer is again a DBR– distributed

Bragg reflector and the last– the bottom layer is a reflective mirror with

99.9% reflectivity.

|

| Cross-sectional image of VCSEL showing different layers |

Note that

the bottom mirror has more reflectivity than the top mirror so that lasing

light can get out from the top mirror instead of the bottom mirror.

The quantum

wells generate photos that travel between the top DBR mirror and the bottom DBR

mirror. This lasing mechanism remains the same in every laser. The quantum

well is made of three layers–a very thin gallium arsenide layer sandwiched

between two thick aluminum gallium arsenide layers. This structure produces

quantum confinement– an effect to increase lasing efficiency.

To know the significant characteristics of the VCSEL and its applications, check our blog: Introduction of VCSEL.

Comments

Post a Comment